When searching for the best type of electric platen for your application, it is important to consider some crucial factors, such as operating temperature and whether the platen should excel at vacuum or non-vacuum applications. You can also start by determining whether you require a platen that is heating only or a platen designed for heating and cooling. If this all sounds like a bit much, we can help; Venango Machine Company offers a wide variety of electric platens (cartridge or strip, single or MultiZone) for compression molders that deliver not only higher temperatures, but faster heating and recovery times as well.

Contact our expert staff today to discuss the best type of electrically heated platen for your application.

Types of Electric Heated Platens

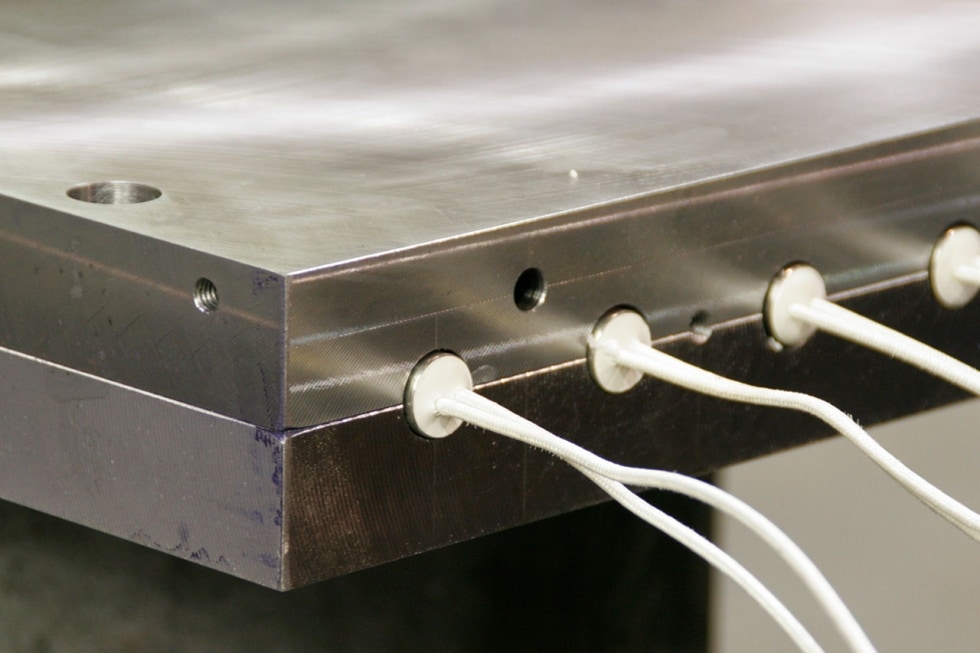

Aside from exclusive MultiZone platen, which we will touch on later, Venango regularly produces four types of electric platens, all designed with different functionalities in mind:

- Strip Electric platens utilize strip-type heating elements. They are often used for lower temperature and non-vacuum applications and offer relatively simple heater removal in case of burnout.

- Conversely, Cartridge Electric platens utilize round cartridge heaters and are most commonly used for high-temperature and vacuum applications. Venango Machine Company also offers a split electric/steam and fluid platen variation of this type.

- Electrically Heated, Water Cooled platens can be produced with both cartridge or strip-type heating elements. A versatile choice, this unique type of platen can be used in vacuum and non-vacuum applications.

- Comprising layers of latticed cartridge heaters and heat tubes, Heat Tube platens are an economical choice for retrofitting projects, especially if you will be pairing them with your current control system. Heat Tube platens are quick and easy to adapt to existing press equipment.

Read more about the benefits of heat tube platen technology.

Considering An Electric Platen Control Panel

Of course, the best way to control certain characteristics or functionalities of your electric platens is with a control panel, and Venango Machine Company is your one-stop shop for single zone (and Multizone) control panels. We recognize the importance of precision and design control panels to meet exact customer specifications. Venango provides stand-alone control panels with the option for a complete operator interface HMI system along with control panel schematics. Additionally, we offer on-site setup and training for these control panels as well as troubleshooting for your electric platens. Not everyone has the time to become a platen expert, and that is why we are committed to assisting you throughout the full process, from selection to installation and beyond.

Choose Electric Platens with Higher Temperatures & Faster Recovery Times

In addition to our wide variety of electrically heated platens, Venango Machine Company also manufactures an exclusive Multizone platen. Paired with its own control panel, this exclusive platen type provides users with the precise level of control necessary to ensure superior products and faster recovery times.

We feel this is the ultimate solution to improving temperature control (and by extension, uniformity), but when it comes to helping you choose the most efficient platen for your application, your needs come above all else. Our knowledgeable team can help you choose an electric platen type that not only meets your specific heating (and cooling) requirements but also excels at keeping superior temperature uniformity. Most importantly, every electric platen we manufacture is custom-designed by our skilled engineers to ensure your specifications are always met.

Contact Venango Machine Company today to learn more about the various electrically heated platens we offer and which is best for your use.