CNC Machine Shop with Precision Blanchard & Large Surface Grinding

Large Capacity Rotary Grinding & Flat Grinding Near Pittsburgh, PA

Over 50 Years of Blanchard & Surface Grinding Experience

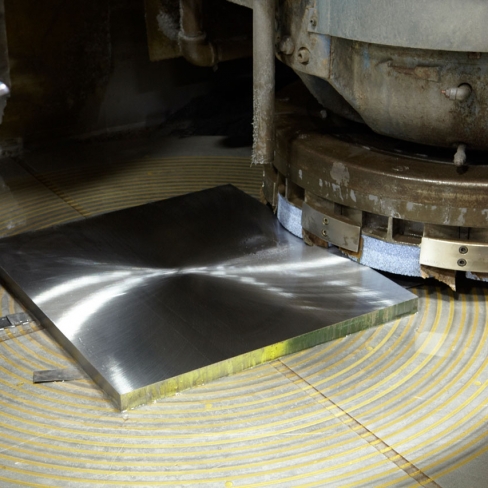

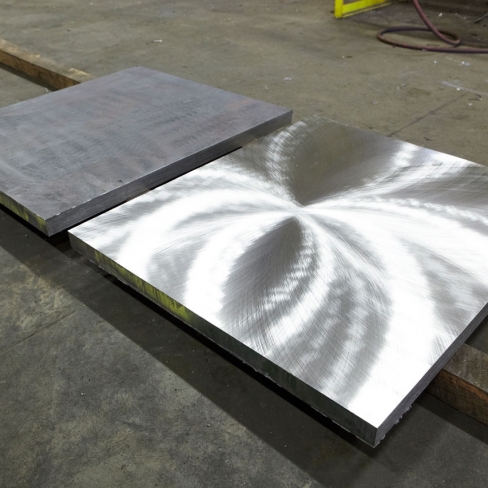

Blanchard grinders are known worldwide as leaders in rotary grinding. In fact, Blanchard grinders are so well known for their quality and precision that Blanchard grinding and rotary grinding have become synonymous. Rotary grinding utilizes high horsepower to remove large amounts of surface stock, leaving a cross-hatched surface finish and providing excellent flatness and parallelism. We have experience working with mild steel, stainless alloys, mold steels, forgings, and castings.

Venango Machine Company utilizes large capacity Blanchard grinders with an 84” swing and a 72” magnetic chuck that holds the workpiece in place. Our rotary grinding operating window is as follows:

- 72″ rotary table

- 84″ swing

- 22″ height

Additionally, Venango Machine can supply your material ground to size, making us a one-stop-shop and eliminating multiple shipping costs.

With over 50 years of Blanchard grinding experience, Venango Machine Company is a leader in flat grinding, rotary grinding, and platen design and manufacturing located 15 miles south of I-90 near Erie, Pa. Customers who work with us not only expect superior quality, but a quick, on-time turnaround on their projects.

Large Metal Horizontal Surface Grinding Services Near Pittsburgh, Pa

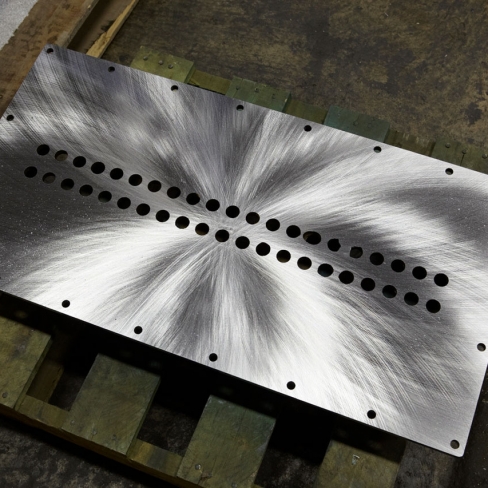

Our Supertec horizontal surface grinder is used for flat horizontal grinding, providing precision flatness and parallelism as well as a smooth finish. This is achieved through minimal stock removal and achieves a low Ra finish. We use an aluminum oxide grinding wheel to assist in removing material, a magnetic chuck, and a traversing machine bed to carry the chuck and workpiece beneath the spindle.

Venango Machine Company can accommodate precision tolerances on mold plates and maintain precision ground finishes on parts up to 118” long. Our surface grinding operating window is as follows:

- 40” wide table (80” capacity with blend)

- 118″ length

- 22″ height

Gallery

Markets Served

Looking for Blanchard or flat grinding services near Erie, PA?

Related News

Large Surface Blanchard Grinding Services

Blanchard grinders are so renowned that the name “Blanchard” has become the de facto name for the process of rotary grinding. Like Band-Aid, TASER, and Xerox, “Blanchard” is a brand…

Blanchard Grinding vs. Surface Grinding: Comparing Grinding Capabilities

Discerning grinding capabilities can be difficult, as many types of grinding fall under the same category, but happen to use separate pieces of equipment. One prominent example of this is…

Expanded Surface Grinding and Gundrilling Capacity

Venango Machine, known for its technology when it comes to precision milling and machining adds new machines to its growing equipment list. The two machines are as follows. Supertec OA-40118…

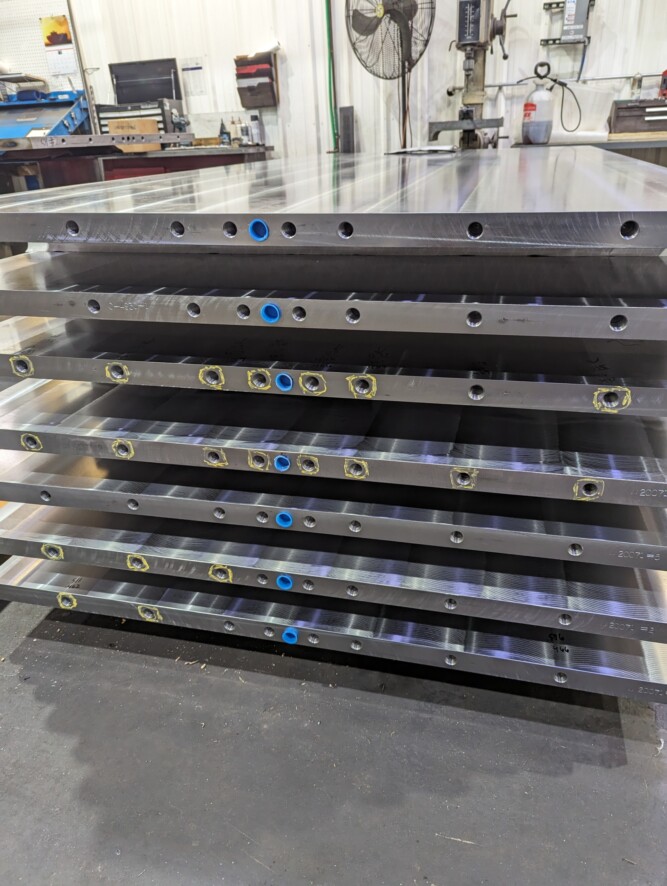

Platens for Heated Compression Molding Presses

Since 1954 Venango Machine Company has been at the forefront of developing new technology critical for subsequent advancements in the rubber, laminate, composite, and plywood industries. One of the manufacturing…

Multi-Zone Electric Platens for Carbon Fiber Manufacturers

Multi-Zone Electric Platens for Carbon Fiber Manufacturers Carbon Fiber Manufacturers Requiring Multi-Zone Electric Platens Throughout history, there have been pivotal moments where the discovery or invention of new materials revolutionized…

Steam & Thermal Fluid Platens for Wood Panels

Steam & Thermal Fluid Platens for Wood Panel Manufacturers Wood Panel Platen Manufacturing with Venango Venango Machine Company opened its doors in 1954 and through a dedication to continual innovation…

Laminate Industry Press Platens

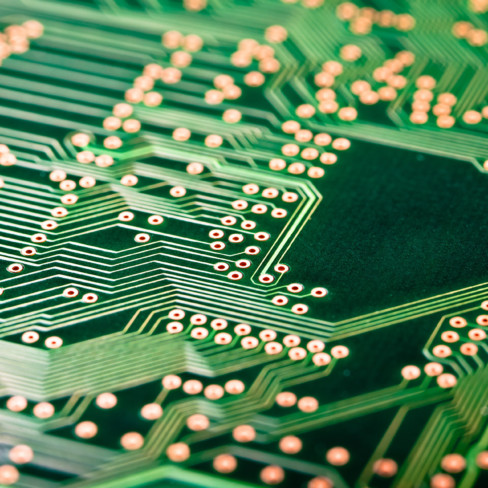

Laminate Industry Press Platen Manufacturing Whether you are a company manufacturing copper clad laminates, simply making prepreg, or producing complete circuit boards, Venango is your source for custom platens….

Custom Platens for Golf Ball Core Manufacturing

Custom Platens for Golf Ball Core Manufacturing Your golf ball manufacturing business needs cores that are produced with the right weight and shape on every press. Venango platens can help…

High Temperature Electric Platens

High Temperature Electric Platens If your company manufactures products using press equipment that requires high temperatures, Venango can provide you with the perfect custom platen solution. We are expert manufacturers…

Manufacturing Multi-Opening Rubber Press Platens

Manufacturing Multi-Opening Rubber Press Platens Contract Venango for a custom multi-opening rubber press platen solution that will ensure your business can produce rubber products uniformly and reliably. A multi-opening press…

An Experienced Multi-Opening Press Platen Manufacturer

An Experienced Multi-Opening Press Platen Manufacturer Multi-opening presses are one of the most efficient ways to manufacture a wide array of products. However, without properly functioning and uniformly heated…