Steam & Thermal Fluid Platens for Wood Panel Manufacturers

Wood Panel Platen Manufacturing with Venango

Venango Machine Company opened its doors in 1954 and through a dedication to continual innovation became the world’s most expansive and longest-running exclusive platen manufacturer. While Venango has become the benchmark for several industries, one that stands out is the design and manufacturing of platens for wood panels. Venango steam and thermal fluid platens for wood panel manufacturers provide cost-effective heating and exceptional pressing capabilities to meet individual customer processing requirements. Our team has the requisite experience to deliver a superior product for companies creating wood panel products including paneling, wood flooring, OSB, MDF, and plywood. Continue reading to learn more about platens for wood panels or start the process of finding the best solution right away by requesting a quote through the link below.

Hot Pressing With Wood Panel Platens

Hot pressing with steam and thermal fluid wood panel platens is a vital step that directly impacts the final quality and properties of manufactured products. Through the hot pressing process, the “book” of layered adhesives and wood products is heated and compressed with variable temperatures or pressures that depend on the final product requirements. Hot pressing cures the resins or adhesives to ensure proper adhesion to the supplemental wood material while simultaneously removing detrimental moisture. Venango platens for wood panels are capable of thoroughly heating several layers of materials and can even handle projects that require increased layer counts of ten or more.

Steam & Thermal Fluid Platens

The primary platen for wood panels are steam and thermal fluid heated platens. Due to the size and continuous operation of these platens, electrically heated options are typically not considered because of tremendous energy demands. Steam and thermal fluid platens offer more economical heating options while still delivering superior performance, uniformity, and the tremendous compression strength required to manufacture wood panels. A premium steam or thermal fluid Venango platen for wood panels will improve your factory throughput, save on heating costs, and result in consistent quality products.

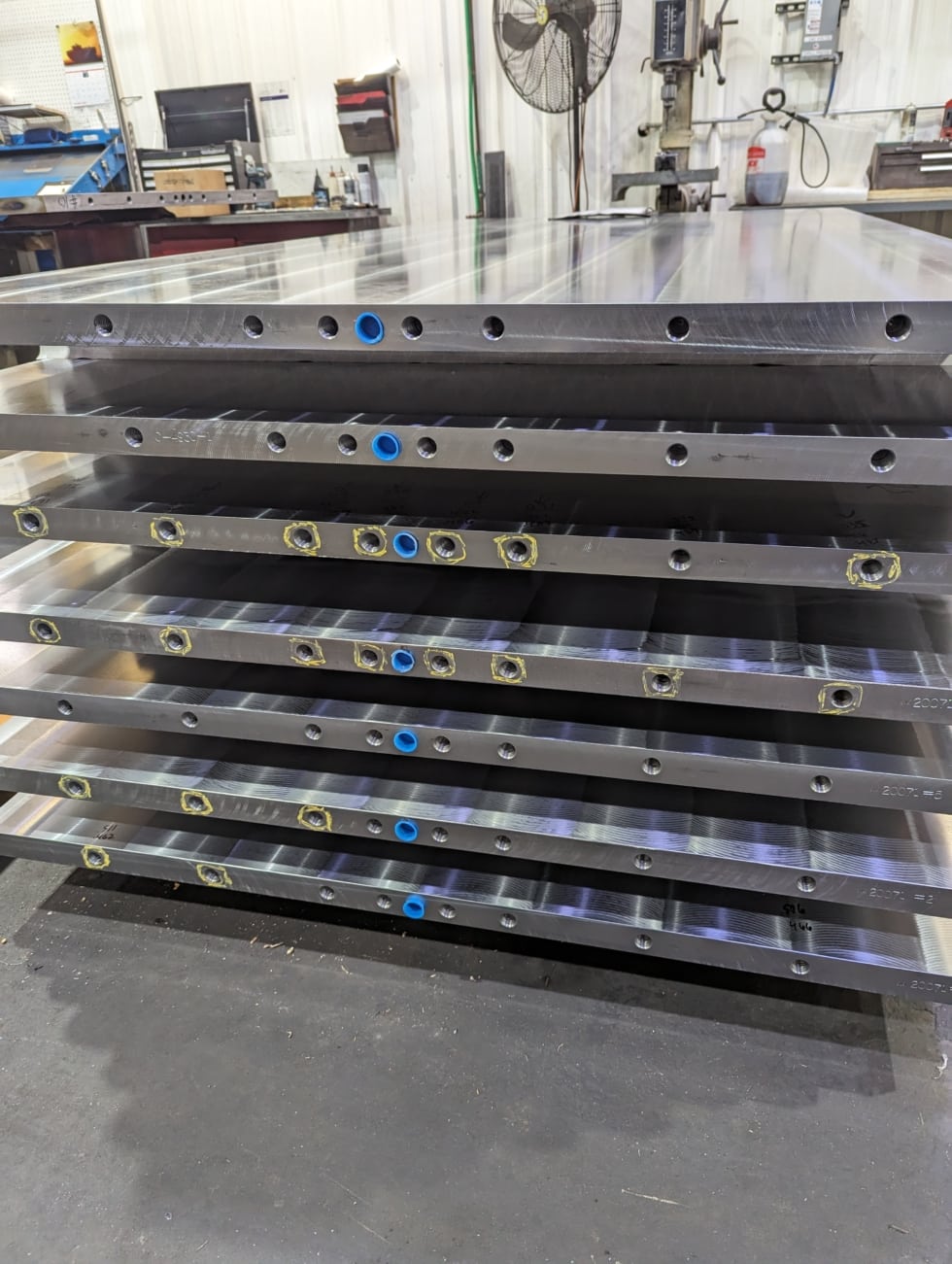

Milled Slot Platens for Wood Panels

While Venango manufactures several different types of platens, the primary type used in wood panel construction is the TYPE MS – Milled Slot Platen. This specific platen design utilizes steam, hot water, or thermal fluid for versatile functionality and impressive durability holding up to the severe heating and cooling cycles required for wood panel creation. Milled Slot Platens offers enhanced flexibility for the number of edge holes required for specific configurations. Additionally, Milled Slot Platens for wood panel fabrication is ideal for the larger 4’ x 8’ standard sheet sizes used in this process. While custom sizes can be created upon request, Venango specializes in the sheet-sized platens found throughout the industry.

Panel & Engineered Lumber International Conference (PELICE Expo)

Venango Machine will once again be attending the Panel & Engineered Lumber International Conference & Expo, on March 14th and 15th in Atlanta, Georgia. With dozens of industry leaders slated to speak, PELICE is the premier educational event for wood product industries throughout the world that require wood panel platens. Companies specializing in veneer, plywood, OSB, MDF, particleboard, and engineered wood products will all be in attendance. If you are visiting the show and are interested in learning more about how Venango wood panel platens will improve your fabrication process, be sure to visit Booth #P303S to speak with our knowledgeable team members. We look forward to meeting with you, discussing your specific needs, and offering our services and expertise to make meaningful improvements in your business.

Choosing Venango Machine for Wood Panel Platens

By combining innovative technology and extensive manufacturing expertise Venango Machine can supply your business with high-quality wood panel platens that meet rigid demands and quality expectations. Steam and thermal fluid milled slot platens offer impressive energy savings and improved efficiency that allow our customers to gain new business and remain competitive within the industry. With both standard and custom platen sizes available, Venango Machine is more than capable of providing a quality wood panel platen for your company. As always, our team is ready to discuss your specific needs and develop an optimized and individual plan that prioritizes your success.