The World Leader in Steam and Fluid Hydraulic Platen Press Manufacturing

Steam & Fluid Platen Overview

Repair and Refurbishing

Steam & Fluid Platen Types

STEAM AND FLUID HYDRAULIC PLATEN PRESS MANUFACTURER FOR THE RUBBER & PLYWOOD INDUSTRIES

STEAM & FLUID HYDRAULIC PLATEN PRESS MANUFACTURER FOR THE RUBBER & PLYWOOD INDUSTRIES

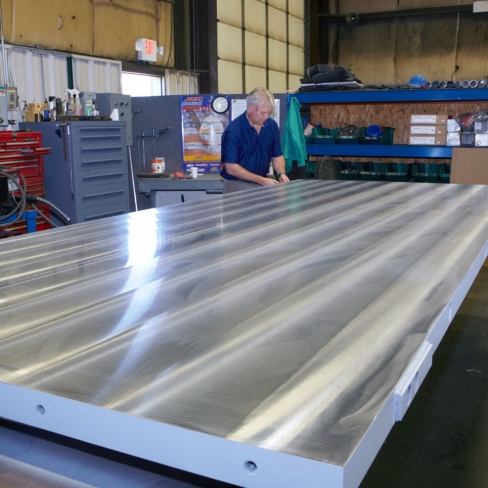

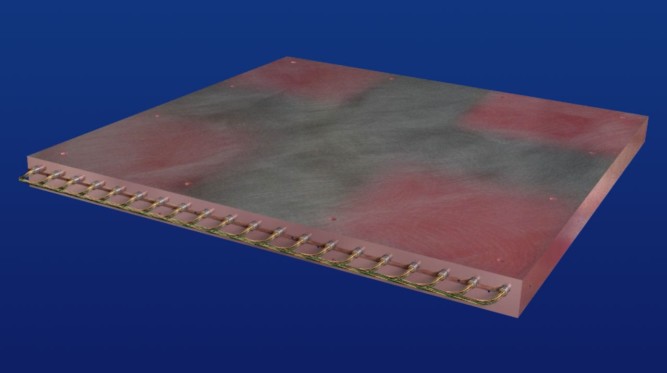

Venango Machine produces steam and fluid platens that are thoughtfully designed for the rubber, plastic, laminating, and plywood industries. These platens provide cost-effective heating and deliver a uniform temperature across the platen plates when molding, pressing, or curing materials.

Venango Machine Company is a premier steam and fluid hydraulic platen press manufacturer. Our skilled team of engineers and machinists can provide the appropriate platen, custom-designed and produced for the rubber and plywood industries.

Steam and fluid hydraulic platen press manufacturers like Venango Machine specially construct steam hydraulic platens for many industries, including:

- Rubber Molding

- Vulcanization

- Bonding

- Industrial Laminates

- Decorative Laminates

- Wood Forming

- Wood Composites

As an established steam and fluid hydraulic platen press manufacturer, Venango advises clients at every step of the manufacturing process. We offer many basic platen designs. Our qualified engineers consider each project’s specifications to ensure that the platen produced aligns with our customer’s needs. From design and concept planning to final platen construction, we will tailor a fluid or steam hydraulic platen for your unique requirements.

STEAM AND FLUID HYDRAULIC PLATEN PRESS MANUFACTURER FOR THE RUBBER & PLYWOOD INDUSTRIES

STEAM & FLUID HYDRAULIC PLATEN PRESS MANUFACTURER FOR THE RUBBER & PLYWOOD INDUSTRIES

Venango Machine produces steam and fluid platens that are thoughtfully designed for the rubber, plastic, laminating, and plywood industries. These platens provide cost-effective heating and deliver a uniform temperature across the platen plates when molding, pressing, or curing materials.

Venango Machine Company is a premier steam and fluid hydraulic platen press manufacturer. Our skilled team of engineers and machinists can provide the appropriate platen, custom-designed and produced for the rubber and plywood industries.

Steam and fluid hydraulic platen press manufacturers like Venango Machine specially construct steam hydraulic platens for many industries, including:

- Rubber Molding

- Vulcanization

- Bonding

- Industrial Laminates

- Decorative Laminates

- Wood Forming

- Wood Composites

As an established steam and fluid hydraulic platen press manufacturer, Venango advises clients at every step of the manufacturing process. We offer many basic platen designs. Our qualified engineers consider each project’s specifications to ensure that the platen produced aligns with our customer’s needs. From design and concept planning to final platen construction, we will tailor a fluid or steam hydraulic platen for your unique requirements.

Platen Types: Steam Hydraulic Platens for Laminating and Board Press Platen Manufacturing

Venango Machine uses innovative technology and manufacturing expertise to produce steam hydraulic platens for customers’ needs. Steam hydraulic platens provide the uniform plate temperature that is crucial to laminating and board press manufacturing. Our customers use laminating or board press platens for manufacturing in various industries and for many applications, including:

- Construction

- Furniture

- Infrastructure

- Automotive

- Packaging

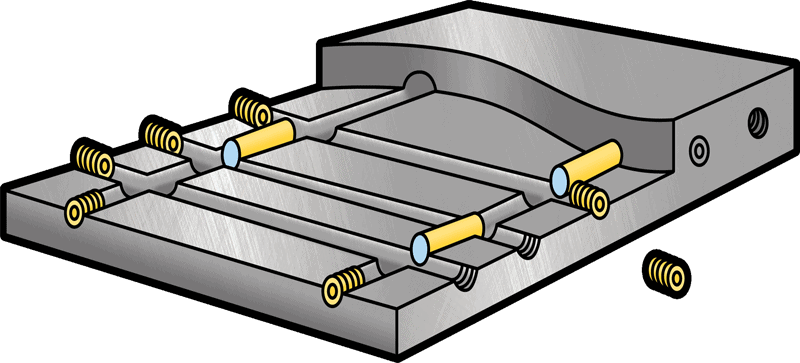

By discussing specific requirements, our engineers can design the platen that will maximize customers’ production and ensure that they have the ideal machinery for their business. The chart below shows the types of steam and fluid hydraulic platen presses manufactured at Venango. If you are unsure which kind of platen is best for your application, contact our sales department for further assistance.

Markets Served

Steam & Fluid Platen Refurbishing and Repair

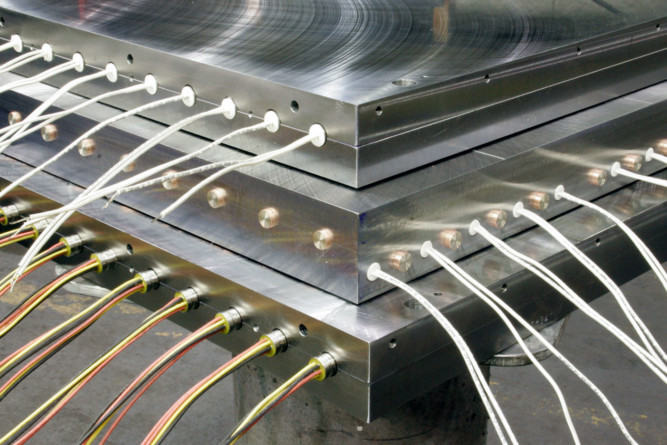

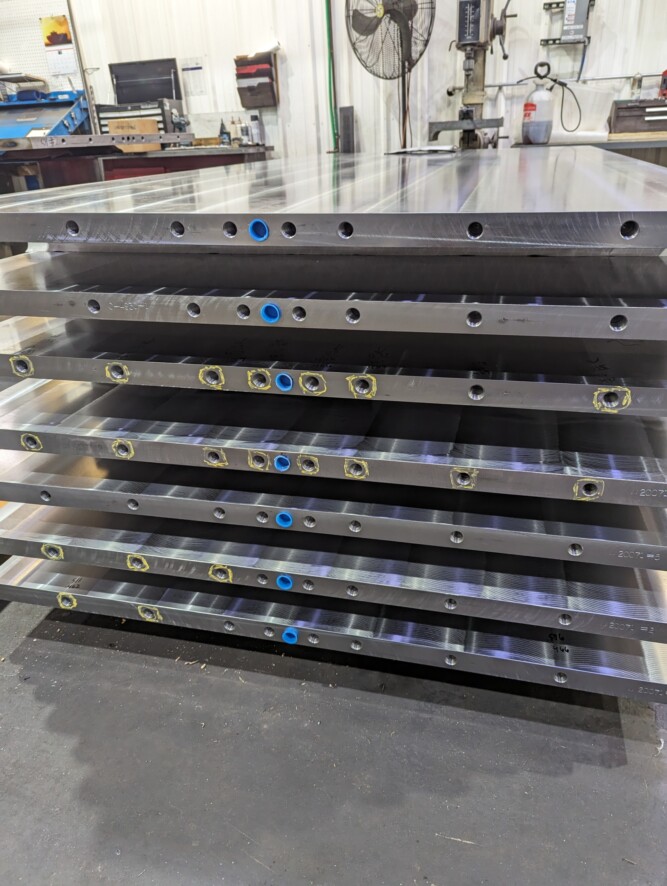

It is crucial to operational efficiencies that fluid or steam hydraulic platens for any application maintain their flatness and parallelism. If a platen is slightly bent, nicked, or gouged, it will produce imperfections in the end product. Lead times begin to lengthen, and customer satisfaction plummets when a platen’s flaws become more pronounced. As a steam and fluid hydraulic platen press manufacturer, Venango Machine Company’s refurbishing program can re-machine steam and fluid platens that have sustained damage in pressing accidents. Furthermore, Venango’s highly skilled engineers are practiced in modifying steam platens for fluid heating, upgrading hanger and guide systems to accommodate additional press openings, and restoring flat and parallel specifications to platens suffering from wear and tear. With an investment in your existing machines, Venango can help operators regain their competitive edge while producing excellent pressed materials, keeping customers happy, and shortening lead times. To learn more about Venango’s platen refurbishing capabilities, contact us today.

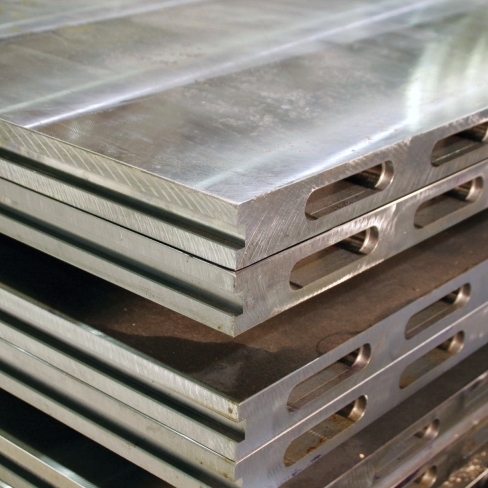

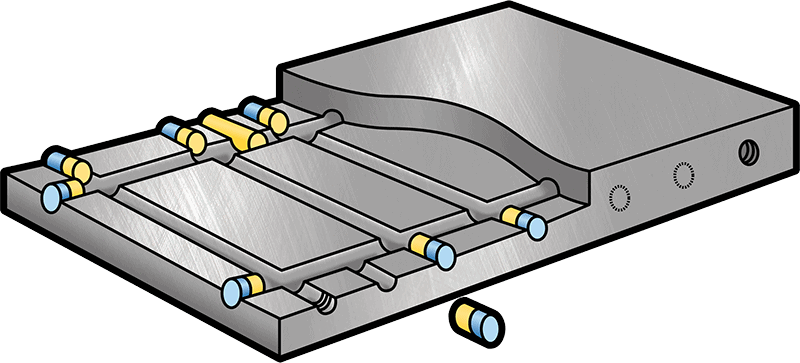

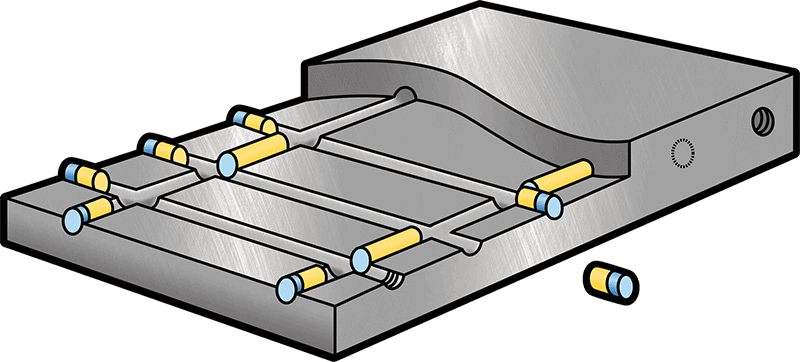

Type PP - Pipe Plug Construction Platen

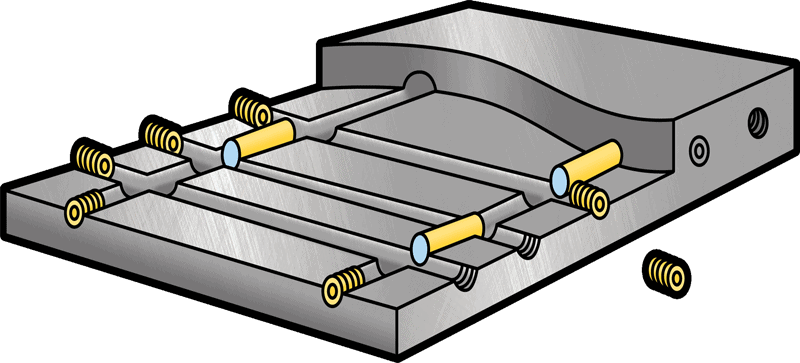

Type SIB - Side Inserted Baffle Platen

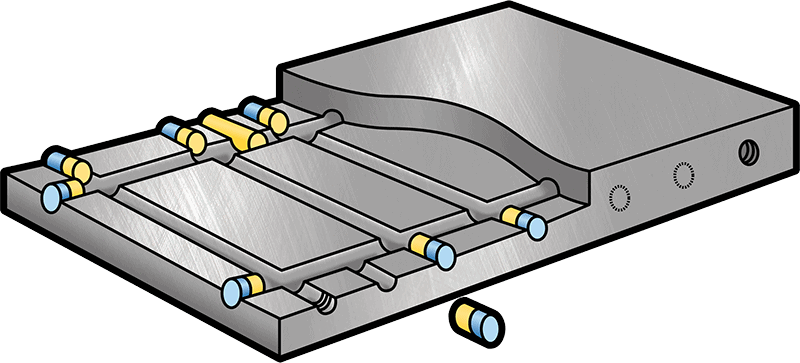

Type WP - Welded Plug Platen

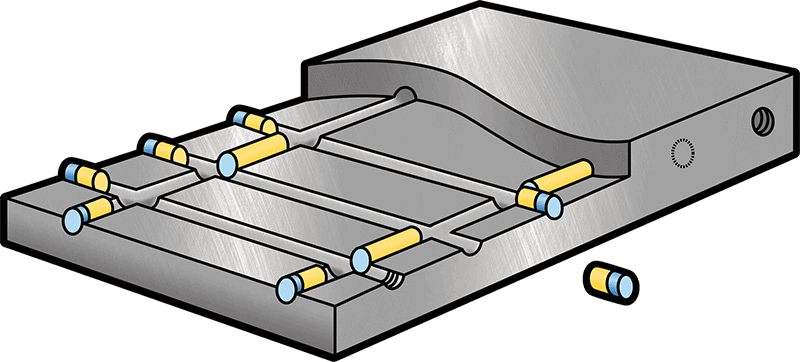

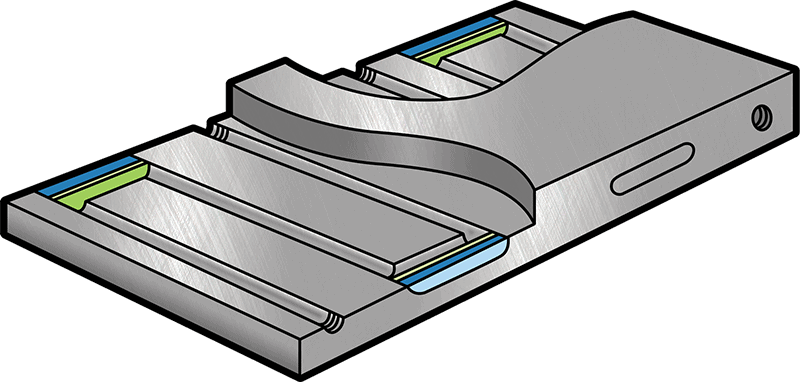

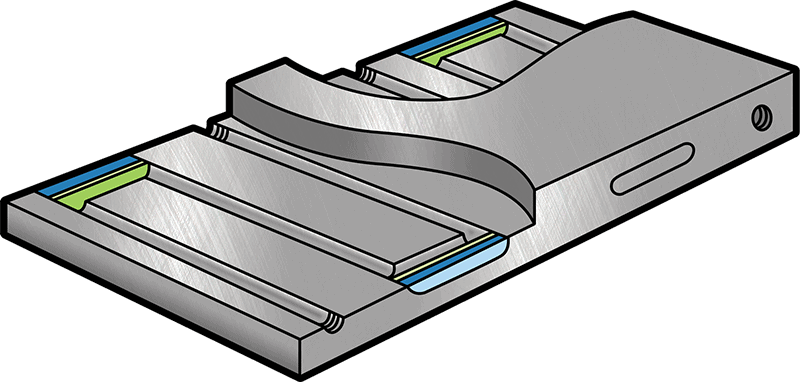

Type MS - Milled Slot Platen

Steam & Fluid Platen Refurbishing and Repair

It is crucial to operational efficiencies that fluid or steam hydraulic platens for any application maintain their flatness and parallelism. If a platen is slightly bent, nicked, or gouged, it will produce imperfections in the end product. Lead times begin to lengthen, and customer satisfaction plummets when a platen’s flaws become more pronounced. As a steam and fluid hydraulic platen press manufacturer, Venango Machine Company’s refurbishing program can re-machine steam and fluid platens that have sustained damage in pressing accidents. Furthermore, Venango’s highly skilled engineers are practiced in modifying steam platens for fluid heating, upgrading hanger and guide systems to accommodate additional press openings, and restoring flat and parallel specifications to platens suffering from wear and tear. With an investment in your existing machines, Venango can help operators regain their competitive edge while producing excellent pressed materials, keeping customers happy, and shortening lead times. To learn more about Venango’s platen refurbishing capabilities, contact us today.

Contact us Today for any of your Steam & Fluid Platens Needs

Related News

MultiZone Platens With the Best Heat Uniformity and Temperature Control

Venango’s heated platens with even temperature control allow manufacturers to introduce zone-specific temperatures while applying forming pressure to molds or directly to materials. This heat uniformity is crucial, as it…

Venango MultiZone Heating Platens Improve Product Quality and Molding Performance

In compression molding, as the value of the material and part rises so does the importance of controlling the uniformity of heat transfer to the mold cavity. Single zone heating…

Platens for Heated Compression Molding Presses

Since 1954 Venango Machine Company has been at the forefront of developing new technology critical for subsequent advancements in the rubber, laminate, composite, and plywood industries. One of the manufacturing…

Multi-Zone Electric Platens for Carbon Fiber Manufacturers

Multi-Zone Electric Platens for Carbon Fiber Manufacturers Carbon Fiber Manufacturers Requiring Multi-Zone Electric Platens Throughout history, there have been pivotal moments where the discovery or invention of new materials revolutionized…

Steam & Thermal Fluid Platens for Wood Panels

Steam & Thermal Fluid Platens for Wood Panel Manufacturers Wood Panel Platen Manufacturing with Venango Venango Machine Company opened its doors in 1954 and through a dedication to continual innovation…

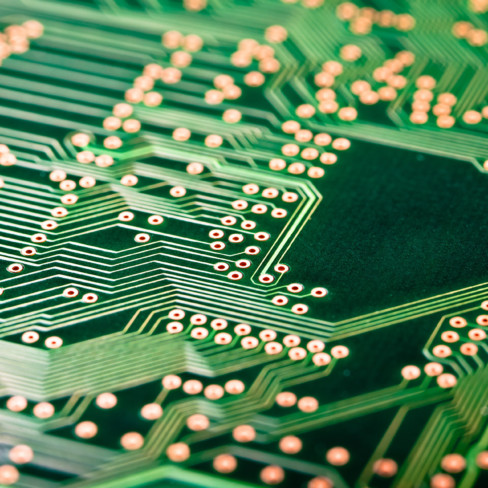

Laminate Industry Press Platens

Laminate Industry Press Platen Manufacturing Whether you are a company manufacturing copper clad laminates, simply making prepreg, or producing complete circuit boards, Venango is your source for custom platens….

Custom Platens for Golf Ball Core Manufacturing

Custom Platens for Golf Ball Core Manufacturing Your golf ball manufacturing business needs cores that are produced with the right weight and shape on every press. Venango platens can help…

High Temperature Electric Platens

High Temperature Electric Platens If your company manufactures products using press equipment that requires high temperatures, Venango can provide you with the perfect custom platen solution. We are expert manufacturers…

Manufacturing Multi-Opening Rubber Press Platens

Manufacturing Multi-Opening Rubber Press Platens Contract Venango for a custom multi-opening rubber press platen solution that will ensure your business can produce rubber products uniformly and reliably. A multi-opening press…

An Experienced Multi-Opening Press Platen Manufacturer

An Experienced Multi-Opening Press Platen Manufacturer Multi-opening presses are one of the most efficient ways to manufacture a wide array of products. However, without properly functioning and uniformly heated…