Venango’s heated platens with even temperature control allow manufacturers to introduce zone-specific temperatures while applying forming pressure to molds or directly to materials. This heat uniformity is crucial, as it affects the dimensional stability and hardness of the component being produced and controls for minimal quench distortion and cracking.

Venango’s MultiZone Heated Platens use electricity to achieve consistent mold temperatures and have unmatched reliability. With dedicated zone control, tracking and sustaining temperatures is quick, accurate, and reliable.

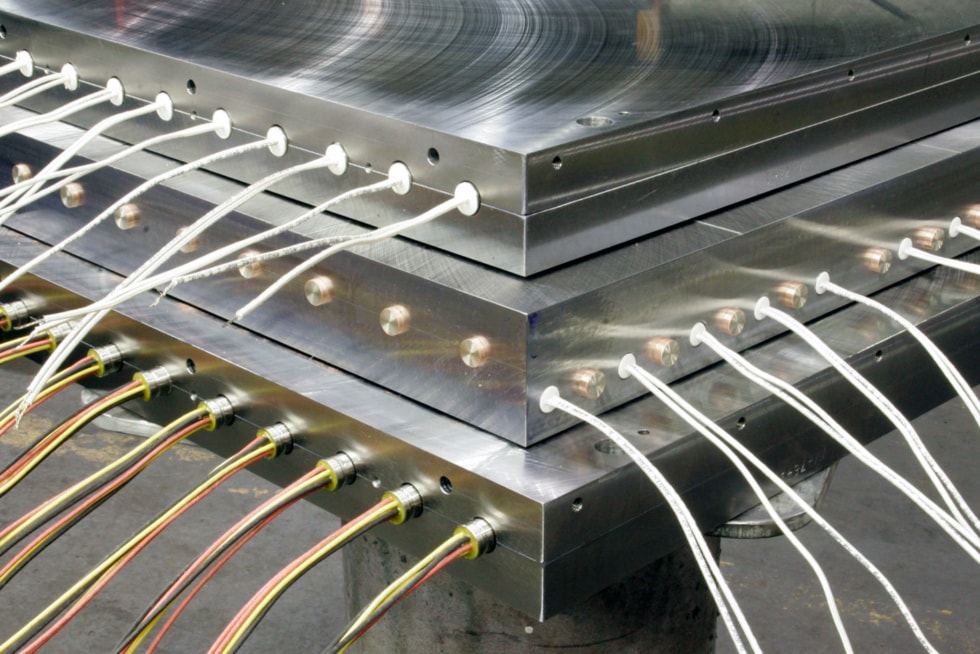

The MultiZone Platen System With Even Temperature Control

How does a Venango MultiZone Heated Platen provide even temperature control? Here are two common questions, answered:

- How are MultiZone platens heated?

Precisely manufactured Venango MultiZone Heated Platens use individual thermocouples and advanced, zone-specific controls. Each platen is divided into nine areas, or “zones.” Heat distribution within the platen is controlled via internal sensors, and heating rates are rapid. MultiZone technology allows for tight temperature profiles on a mold’s surface. In fact, Venangos proprietary MultiZone Heated Platen significantly reduces mold surface temperature variation, placing it among the platens with the best heat uniformity available today. - How is platen temperature controlled?

The precise performance of a Venango MultiZone Heated Platen is directed by its state-of-the-art control panel. Venango has a unique stand-alone control interface with the option of a complete operator HMI system, including control panel schematics. Venango provides initial control panel engineering, on-site setup and training for our control panels, and troubleshooting for any electric platens.

Why Molds for Composite Material Manufacturing Require Uniform Heating

Each platen’s unique ability to control the temperature of different regions, or “zones,” means that individual mold areas only receive the heat necessary for the treatment of the material contained there. This acute mold-temperature control is a hallmark of Venango’s MultiZone Heated Platen.

In compression molding, as the value of the material and part rises, so does the importance of controlling the uniformity of heat transfer to the mold cavity. Single zone heating platens can not correct temperature variation across the mold face, negatively impacting manufacturing and part quality and increasing scrap rates.

“Maintaining good temperature uniformity over the surface of a platen is extremely difficult. The MultiZone platen is superior to heat tube platen technology because the key is uniform mold temperature, not uniform platen temperature. MultiZone platens with even temperature control give molders six sigma capabilities,” said Nyla Vogel, Sales Manager, Venango Machine.

Venango’s MultiZone heating platens and their comprehensive control systems reduce mold surface temperature variation by almost 400%, delivering the precise control necessary to ensure a good product and faster recoveries, saving time and money.

Industries Benefit From Platens With Even Temperature Control

Platens with even temperature control provide quick, consistent production with minimal waste and downtime – the ultimate goal in manufacturing. A heated platen press should last for many production cycles without warping or diminishing its ability to provide consistent temperature. Selecting a platen with the best heat uniformity is critical to ensuring the longevity and performance of a manufacturer’s platen equipment.

Many industries benefit from Venango’s platens with even temperature control, including:

- Rubber Molding Industry:

Rubber gaskets and o-rings are used across industries in products ranging from water pumps and air filtration systems to food-safe seals and medical equipment. Using platens with the best heat uniformity is fundamental to delivering the right temperature to molds for rubber components. Even mold temperatures underpin the critical vulcanization process that rubber materials undergo for gaskets to emerge elastic, resilient, and hard-wearing. - Manufactured Wood Industry:

For an industry that produces engineered wood, using platens with the best heat uniformity is key to producing reliable, resilient products. Particle board, chipboard, plywood, and fiberboard rely on specific, even mold temperatures for their bonding adhesive to cure. Uneven heating during pressing can undermine the cohesive strength of manufactured wood products. - Lamination Industry:

When composite materials need enhanced strength, stability, insulation, or appearance, the lamination industry depends on heated platens to apply the necessary coatings or finishes.

When paired with technologically advanced control panels that closely monitor heat distribution, manufacturers can rest assured that their molds won’t suffer from common pitfalls that cause production breakdown.

Platens With the Best Heat Uniformity

In comparing single-zone versus MultiZone heating platens, temperature uniformity improved from 25 degrees off-target to only 0.4 degrees. Further, the CPK increased from -1.47 to 2.94 while lowering the standard deviation from 3.2 to 1.08. During molding, the process window dropped from +/- 9.6 to +/- 3.2, ultimately leading to shorter cure times and lower scrap rates.

Venango MultiZone Heated Platens Have the Best Temperature Control

Maintaining exceptional temperature uniformity over the surface of a platen and on a mold itself is crucial. At Venango, our exclusive MultiZone Platen technology makes heat control easy and precise, and our control panels are equipped with sophisticated software to allow careful temperature monitoring. When the quality of your product depends on even heat, Venango’s MultiZone Platen is the best choice.

Consult with Venango today for more information about our MultiZone Heated Platen presses.